Let’s start off this blog with a sobering reality. The construction industry’s concern for worker safety is often downplayed, despite being a crucial priority. As far back as 2015, the Frontiers of Engineering Management highlighted this truth:

“Although safety is a priority to all parties involved, it is not uncommon that safety and other construction management practices take a backseat to schedule when faced with liquidated damages and lost profits.”

At no time is this more evident than when a construction project is faced with potential delays. As every construction professional knows, delays are inevitable. There are plenty of reasons why they arise. Some are related to the initial schedule (overly optimistic delivery dates). Others are unavoidable (weather, supply chain issues).

The Industry’s Popular Solution: Compression

In many of these scenarios, construction industry professionals turn to schedule compression. Compression is defined as “reducing the project schedule duration while maintaining the project scope and quality.” While different terms like crashing, acceleration, or trade stacking, are synonymous with compression, there are two main compression techniques:

- Fast Tracking: A schedule compression technique when activities that would have been performed sequentially based on the original schedule are performed at the same time (in parallel or in partial parallel with one another).

- Project Crashing: When cost and schedule tradeoffs are analyzed to determine the greatest amount of “compression” for the least amount of additional costs and/or resources.

Both techniques can be very effective if used sparingly – and judiciously. Unfortunately, “compression giveth and compression taketh away.” In other words, while it has numerous tangible benefits, it can present some risks. And one of the most consequential is in the area of worker safety – an area that, as demonstrated by the opening quote, already gets shortchanged – especially when a schedule is “over-compressed.”

Worker Safety Concerns with Compression

Safety issues related to schedule compression can be broken down into several categories. While these are not all of the potential safety concerns, it’s safe to say they are the most prevalent.

The Use of Overtime

This is probably the most frequently cited cause of worker injuries. When working longer hours to meet a schedule, construction workers grow more tired. As a result, they can lose focus, leading to carelessness and accidents. And because of the physical nature of construction activities, the consequences are generally worse than someone working an office job.

The amount of overtime is a significant factor as well. A Frontier’s Journal study titled “Schedule Compression Impact on Construction Project Safety,” revealed interesting insights. The duration of overtime had a statistically significant impact on the number of safety incidents. In addition, many contractors contend that workers tend to be less alert at night due to their accustomed daytime work hours, making nighttime work riskier.

Reliance on Nighttime Work

Over-compression of a construction schedule can mean that nighttime or overtime work is required. This presents its own unique risks. Multiple studies have determined that safety and productivity are reduced on night shifts.

These challenges include limited visibility at night. Even with the best lighting, it’s almost impossible to light up an entire construction site, especially on larger projects. Moving heavy equipment around the site is also limited because darkness can make it hard for operators to spot their fellow workers. And even when the construction site is well-lit, glare from passing vehicles and spotlights can temporarily create blinding conditions. Additionally, workers operating high above the ground and operating heavy equipment are at the greatest risk.

The Need for Additional Resources

The crashing technique of compression means that additional resources will be added, which usually means more workers. With a labor shortage still plaguing the construction industry, some of the added workers may lack experience. This can lead to accidents, not only to themselves but to others on the job site. Even if the new workers are adequately skilled and experienced, they still need to “meld” with the existing team, becoming familiar with the job-site routine. This does not happen overnight, and a number of safety problems can manifest themselves until it does.

In the fast-tracking method, there can be more workers on the job site at the same time, given that some steps that were going to be sequential are now being performed in parallel or at least partially parallel. Exact statistics are difficult to find, but logic would suggest that the more people on a job site, the greater the chances that overall worker safety will be affected.

The Impact on Mental Health

Decreased mental health as a byproduct of over-compression is a genuine concern vis-a-vis worker safety. Overtime can be a physical risk, but it also takes a toll on a worker’s mindset. Specifically, it’s the scheduled overtime that exerts the greatest negative impact. Workers can usually tolerate being asked to handle overtime now and then, but seeing an overtime schedule with their name on it multiple times is highly demoralizing. It can result in “presenteeism” when a worker is on the job site but is not fully engaged due to a lack of focus or concentration.

The other concern is the pressure of meeting a deadline that is already under intense scrutiny. Workers not only have to up their game in terms of productivity, but they must also do it while feeling the eyes of their managers searing into their backs. What’s more, from a physical standpoint, the hazards of rushing in the workplace are well known.

To Compress or Not to Compress: That Is the Question

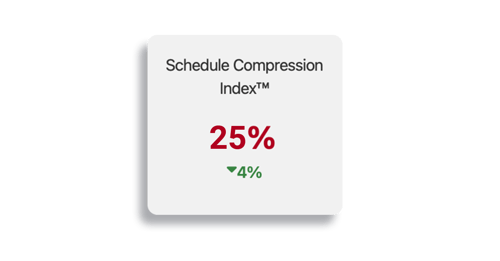

Begin quantifying compression to understand it. By calculating compression levels, you can effectively manage and avoid the instability and safety concerns associated with highly compressed construction projects. Tools like SmartPM automatically calculates the compression level within your schedule by comparing planned versus actual progress and send warning signals once your Schedule Compression Index™ exceeds 25%.

SmartPM recommends the compression metric should not exceed 25% because this is the level where an extra workday per week (Saturdays) becomes insufficient, and 25% more workforce is required to reach a deadline. However, this assumption relies on the critical and near-critical trades achieving the intended productivity, which is unlikely due to the safety and productivity challenges with over-compressed schedules, as discussed earlier.

None of this means that a contractor should not completely avoid the use of schedule compression techniques. What should be avoided is over-compression. It tends to create an environment where productivity may actually not even be increased. It also puts worker safety at risk. Consider the human factor in your compression strategy – it’s the right thing to do.